Simple Detailed Vector

$7 to $12 mostly $7

- This Category Includes Signs, Icons, Simple Silhouette etc.

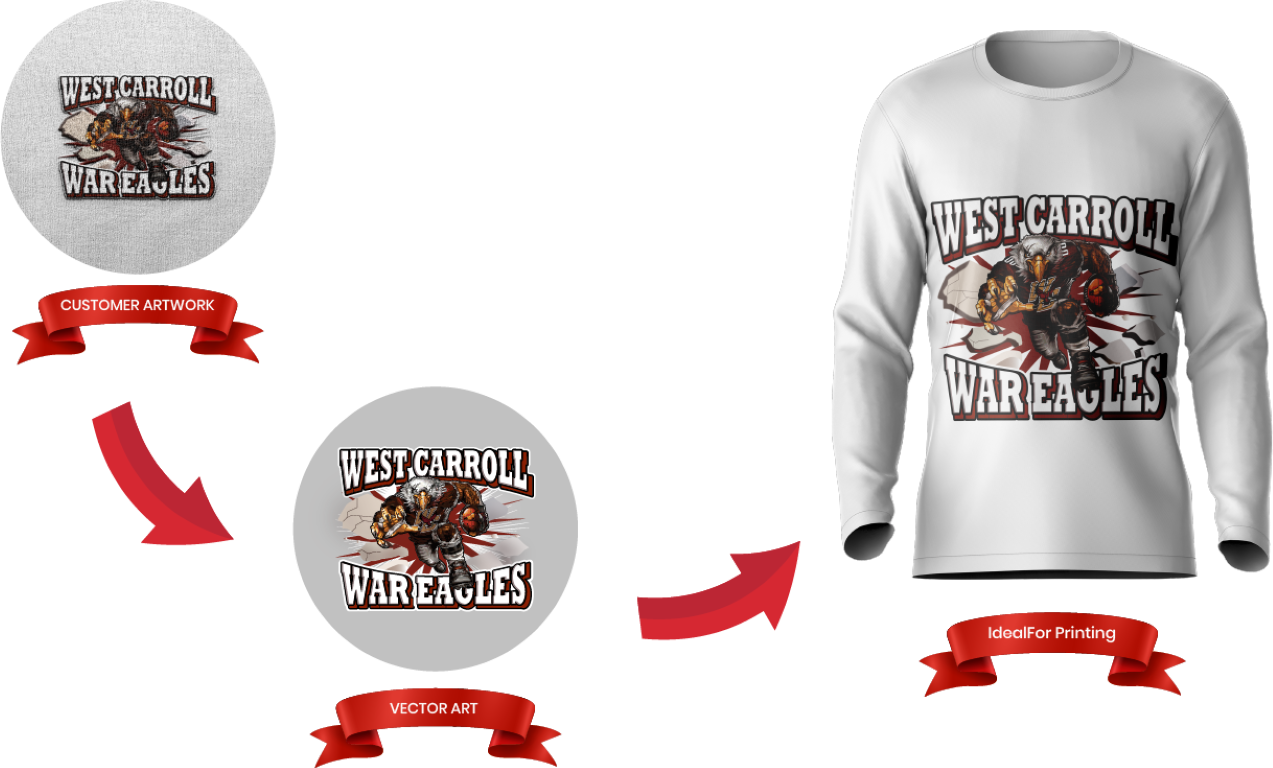

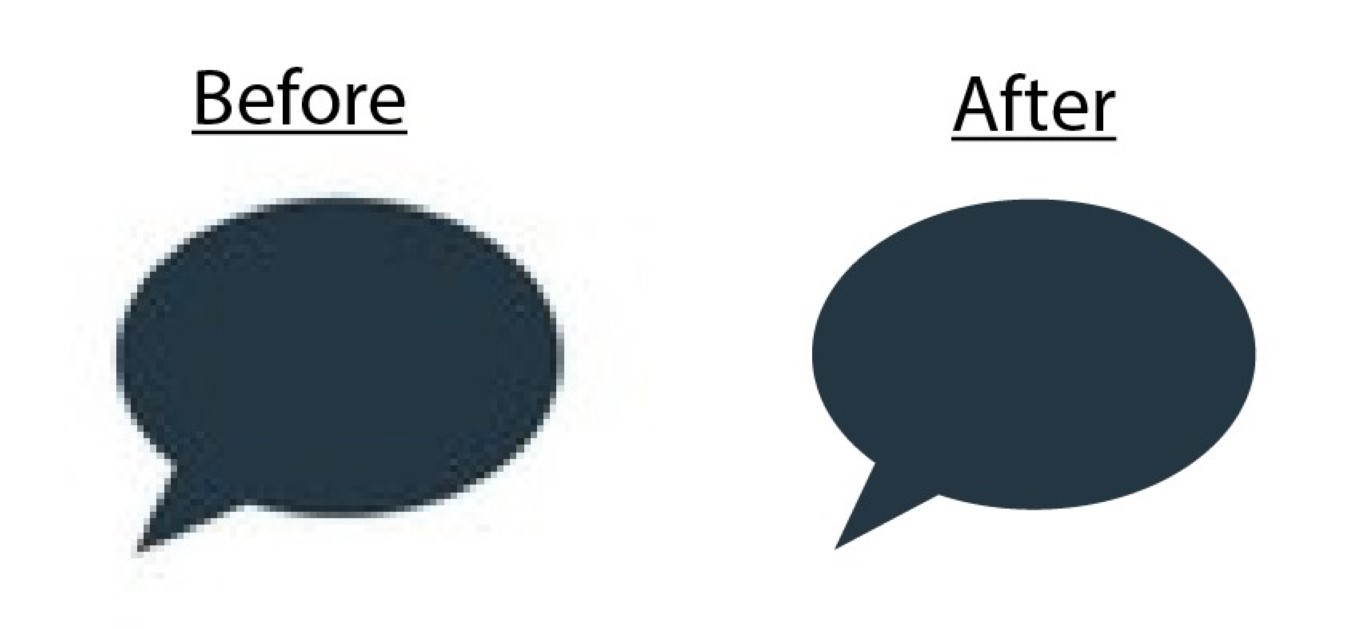

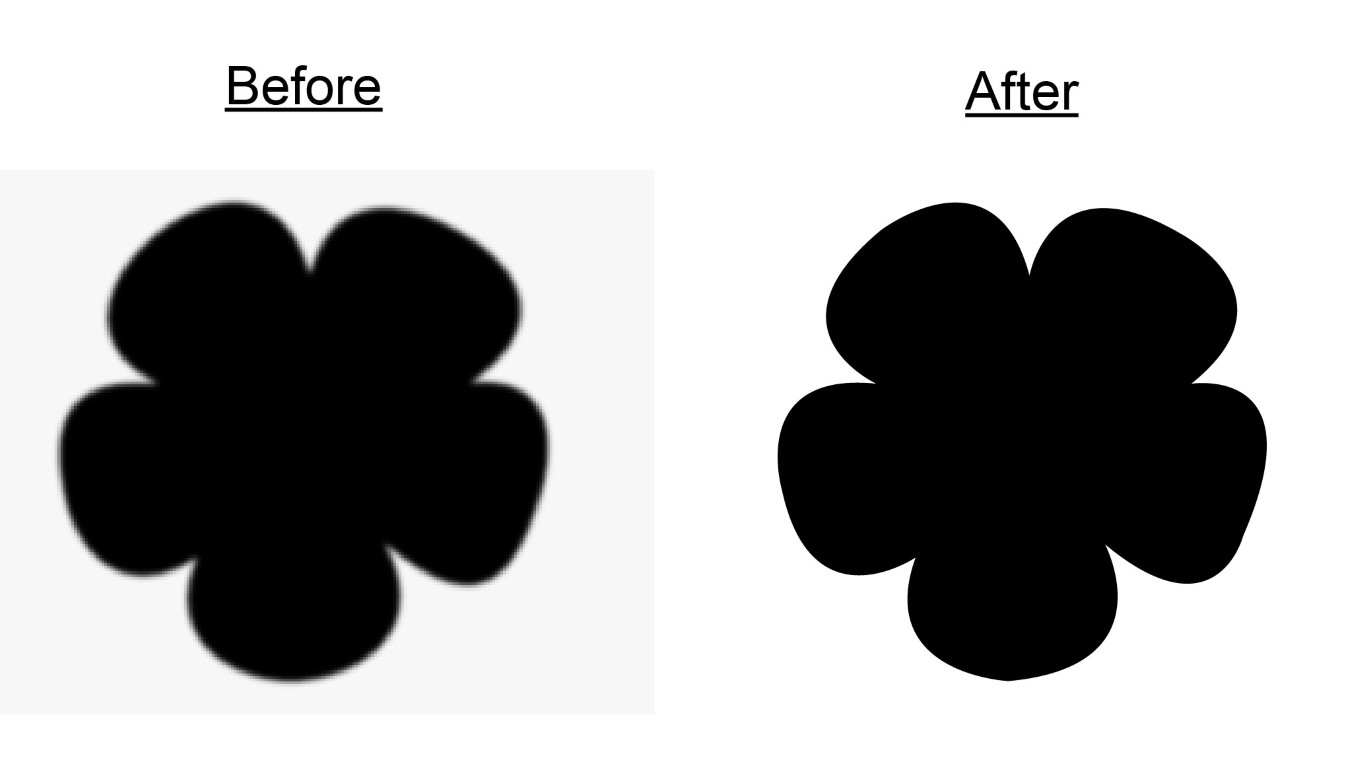

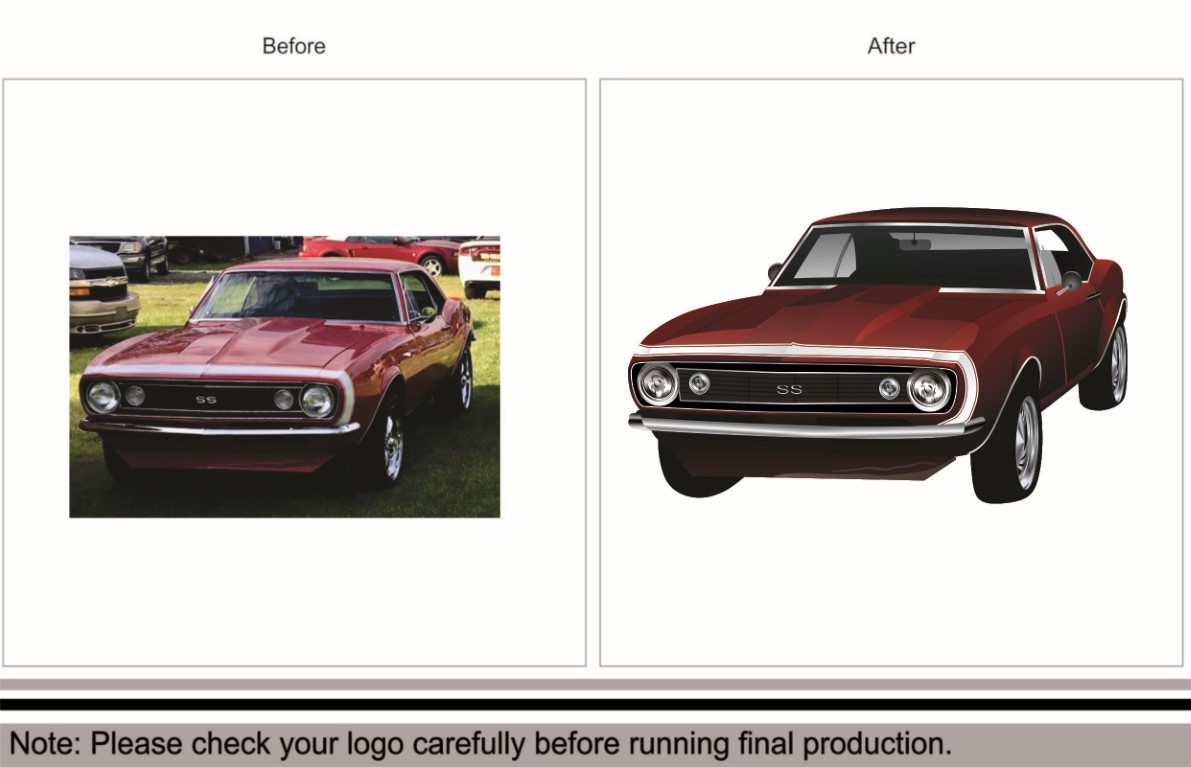

The process of converting bitmap files JPEG,PNG,BMP etc. or even a camera taken picture into a proper straight and even Vector file which mainly is required for printing for better results a vector art is scalable to any size you might need without losing quality on the other hand bitmaps files aren't scalable for better understanding find the Image below:

My Image looks fine I don't think It would need a vector? A Bitmap file (JPEG, PNG, BMP etc.) though it might seems that it's perfect and will print fine but for real it does not by zooming in the Image you would see that the edges aren't smooth that will be very visible after printing and of course the background is there too that will print along with it.

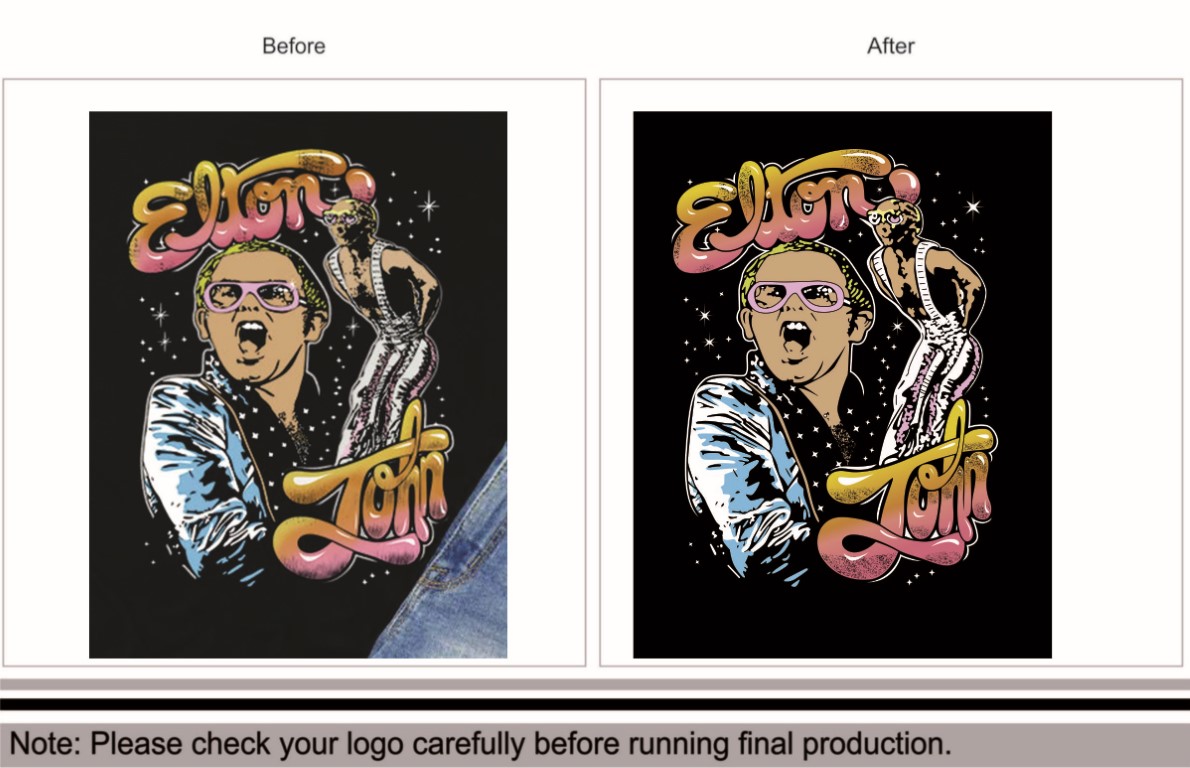

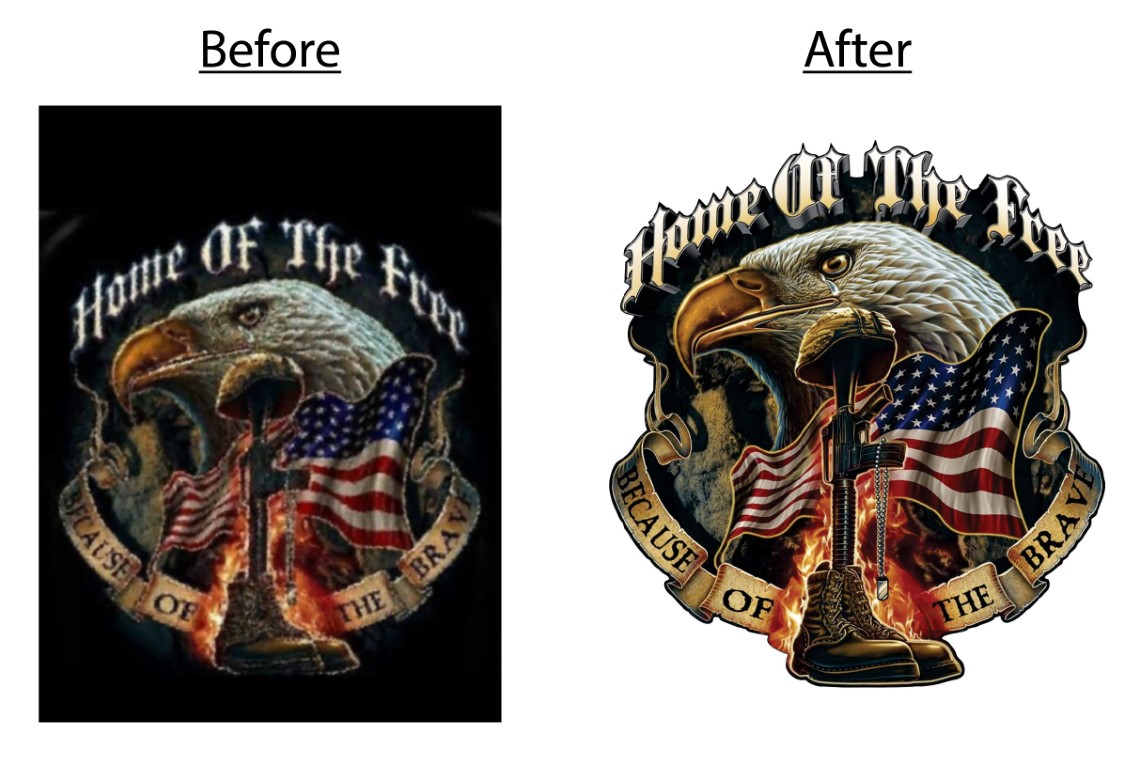

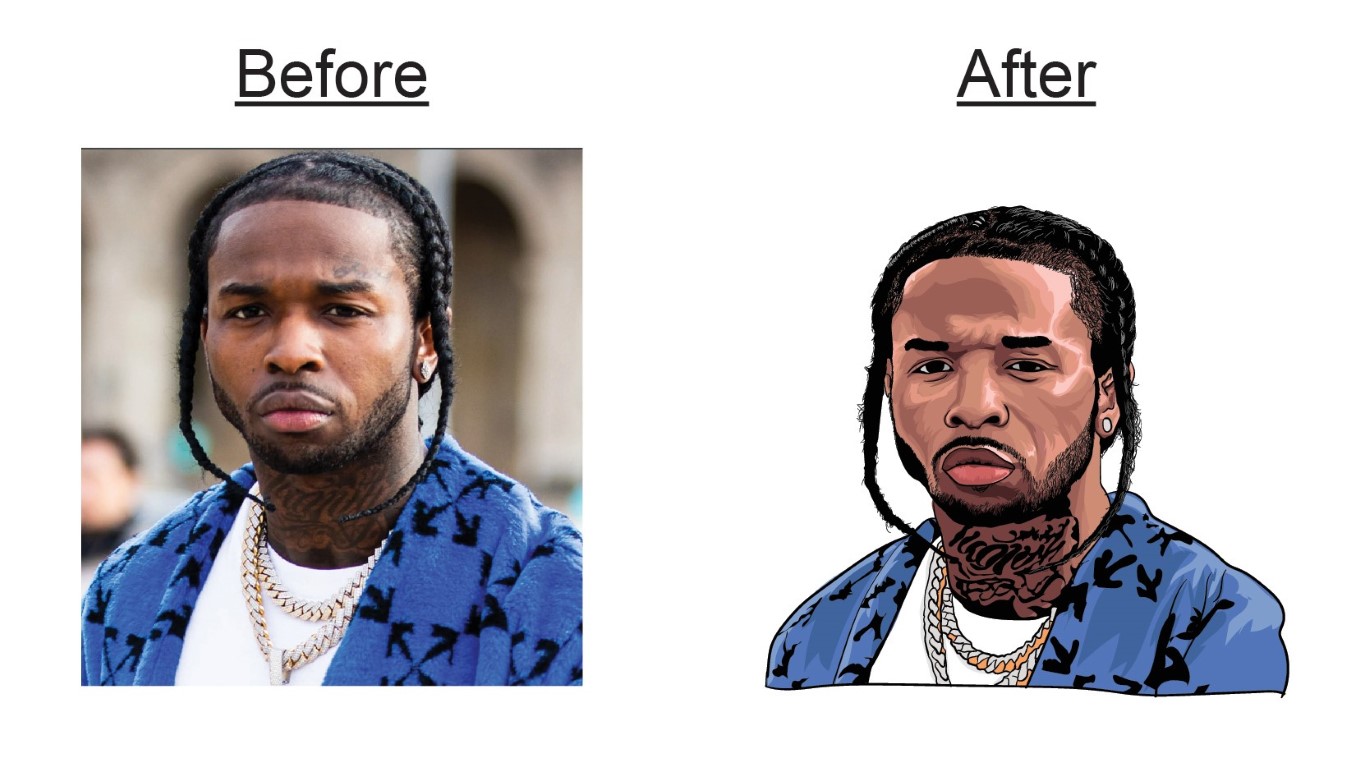

We Here At Billys Custom Digitizing love to Restore Bad Artworks and Vector it we've been into this for the past 20 years with more than 40 Vector Artists On Staff with a head of 1 vector Artist Each team of 5 with an experience of at very least 5 years you get nothing but quality with us.

In this type we convert simple signs or icons etc into Vector

In this type we convert simple signs or icons etc into Vector

In this type where we convert Everyday logos into Vector Art.

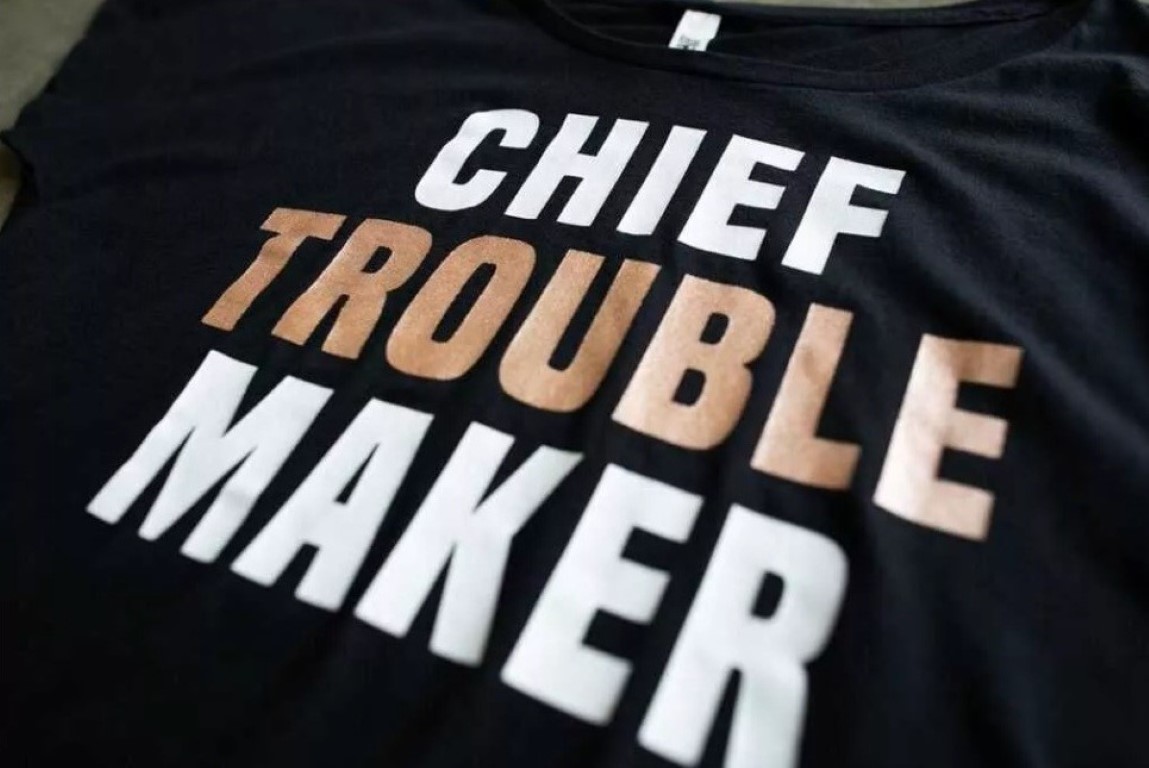

In this Type We Convert Artworks/T shirt Designs into Vector Art

In this type we don't Fully Vector Artworks some part of it is vectored and someone and in some cases nothing is vectored what we do is Create a Transparent No Background PNG file and print it this is usually use for Direct to Garment DTG and Sublimation it can also be used for Screen Printing though it would needs a PSD Separation Also by all means this doesn’t this method is usually used to save up on cost if one wants to Vector the whole Artwork that can be done too.

In this category we convert Cars, Bikes, Train, Tuck, Houses Literally anything you capture from your camera into a Vector Art

In this Category we convert you Human or Pets ar any Living thing or anything into a Vector Art the details used in the Vector though is subjected som/website Images have Super high details liek the one showed below and some can have a very little details.

In this Category we Create Custom Order Temlate for you where we will palce your logo on it and customiz it accoridng to you then we put your customers designs onto digital apparel on your desired location you can use it to send digital mockups to your customers to give them more clarity about there order and getting approval becomes easier

Spot color is the most common print technique in the industry, Knowledge of creating, applying and handling spot colors is essential to any screen printer. Logos, text, cartoons, line art, and more are all styles spot colors excel at reproducing. Spot color designs are usually created through the use of vector graphics programs such as Adobe Illustrator and many more. Spot colors (such as Pantone or custom mixed) can be printed as solid shapes at 100% tint or halftones by changing their tint value away from 100%.

Traditionally limited to solid color with some halftones and vector illustrations. Spot color does not reproduce every kind of print; for example, it doesn't work for photographic designs. Manual user file preparation (under-basing, choking, spreading).

Vector graphic programs like Adobe Illustrator

CMYK is the oldest color reproduction print method. Screen printers. can print designs on white or light-colored garments using cyan, magenta, and yellow. For users skilled in CMYK file preparation, Photoshop, and screen creation, this is still a viable print process for light-colored garments. CMYK is implemented less because simulated printing is more dominant.

Use Photoshop to separate colors. Do not use a vector program to separate.

Simulated Process is a method used to reproduce almost any image. It does so by overlapping and blending colors in a method similar to CMYK through using halftones and spot colors and/or PMS colors. Essentially, it's a way of taking an image that historically would have been printed via CMYK, but instead uses more opaque ink to create a more stable color and production friendly ink that can print almost any design for any garment. Designs that are too difficult to separate in a vector program, raste/website images, photographs, complex tonal illustrations detailed artworks or designs with a huge amount of colors — all doable with Simulated Process. Since the 90’s, Simulated Process has become more prominent and widely accepted because it's easier to separate, print, and achieve the best, completed garment compared to CMYK. Simulated Process is more stable during production, resulting less misprints. It's the preferred separation printing method. With any new technique, a printer should thoroughly research the method and practice before implementing in their shop. Look online for information. Facebook groups like Rogue Printers is a great place to ask experienced printers for help. YouTube is another great platform to learn more about the process. If you do not have the bandwidth to learn more about separations, freelancers that specialize in separations can help you.

Photoshop or other program

We Use the most used professional and expensive software all Major Embroidery Software's that includes Wilcom, Pulse, Melco etc. we say no to software piracy

There are multiple types of printing and engraving while creating the designs when creating Designs we must know that for what kind of medium we're creating for so we can create them accordingly below are printing methods commonly used

Screen printing is the process of pressing ink through a stenciled mesh screen to create a printed design. It’s a popular technique used in a whole range of different industries, so even if you've never heard of the term before today, it’s likely that you’ve worn or used a screen-printed product at some point without even realizing. The process is sometimes called serigraphy or silk screen printing, but all of these names refer to the same basic method.

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. Meaning: It goes directly from your PDF file, for instance, straight to the digital printer. There is no need to create any plates, and setup time is a fraction of the time offset printing would take.

Digital printing usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume or inkjet printers.

A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time. While heat presses are often used to apply designs to fabrics, specially designed presses can also be used to imprint designs on mugs, plates, jigsaw puzzles, caps, and other products.

Heat transfer vinyl, or HTV for short, is a specialty vinyl polymer that can be used on certain fabrics and materials to create designs and promotional products. It comes in a roll or sheet form with an adhesive backing so it can be cut, weeded, and placed on a substrate for heat application.

A vinyl cutter is an entry level machine for making signs. Computer designed vector files with patterns and letters are directly cut on the roll of vinyl which is mounted and fed into the vinyl cutter through USB or serial cable. Vinyl cutters are mainly used to make signs, banners and advertisements. Advertisements seen on automobiles and vans are often made with vinyl cut letters. While these machines were designed for cutting vinyl, they can also cut through computer and specialty papers, as well as thicker items like thin sheets of magnet. In addition to sign business, vinyl cutters are commonly used for apparel decoration. To decorate apparel, a vector design needs to be cut in mirror image, weeded, and then heat applied using a commercial heat or a hand iron for home use. Vinyl cutters are mainly used to make signs, banners and advertisements

A dye-sublimation printer is a printer that works by heating ink and then depositing it on a surface. The term arises from the misconception that the ink goes from solid to gas without going through a liquid phase, or sublimation. Dye-sublimation printers are used for printing photos and designs on solid objects

Laser engraving is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly. There are multiple objects on which you can engrave like Wood, Metal .Acrylic , Glass, Etching, Leather ,Stone, Marble, and Granite.

We are a team of digitizing experts who have been doing this for over 20 years and have been doing it for the past 20 years. We have a team of 60 plus digitizers with a head of each team at least 10 years of digitizing and 2 years of machine experience and a R & D team who constantly keeps an eye on new technologies an how ot improve our services we've been doing this since it was done on Graphs.

Customer bring in an Embroidered hat with a side angle design i don't know how but these guys were able to create a perfect vector out of it you guys are amazing keep up the good work.

Private Review

Top Notch service but what I like even more was how they explain things for instance there was this Artwork that I was goanna DTG. Every other company gave us insane pricing because of course that was intricate but they told us we can create a high Res PNG that'll be cost efficient as well as it works perfect for DTG long story short top notch support team they know what they doing.

Private Review

Billys Did a Very Busy Vector Art for me the challenging part was when I was needing the color sep done lots of colors for screen printing as I was new to screen printing didn’t have a clue however they guided me with the correct options Simulated Color Sep very Satisfied Would recommend to anyone Billy you're Amazing :)

Private Review

We do all types of printing here at our shop and using Billys Custom Digitizing they do wonderful work fastest turnaround I once sent them a Sketch and they converted into a perfect vector Highly recommended.

Private Review

So My Concern Was Color Seps I do screen printing and Signs Billys Custom Digitizing they know how to create print ready colors seps and what separation method to use design to design which I wasn't able to find in tons of Vector Artist I've used which is great to have these guys are BRILLIANT.

Private Review

I'm amazed by the results they accurately vectorize the Image that one can't even tell if there's any difference from literally very bad qualit/website Images Highly Recommended.

Private Review

Magic the Image Quality was very bad that I couldn't tell a thing restored it perfectly. Keep It Up Guys.

Private Review

I can’t say enough about the wonderful work that Billy’s Custom Digitizing does!!! I send some of the most intricate designs and he makes them look Perfect

Private Review

I would recommend Billy’s custom digitizing. Very clean work fast turnaround and spot on with details. Professionalism at its best. Thanks for the great work.

Private Review

I've recently sent some super intricate designs to Billy's Custom Digitizing and very satisfied from how they've printed these guys know what they doing Money can Buy.

Private Review

Billys Custom Digitizing does amazing work what's even better about them is they're easy to communicate over the phone and it feels like talking to the Designer directly Shawn and Billy are amazing keep up the good work guys

Private Review

$7 to $12 mostly $7

$12 to $20 mostly $15

$25 to $35 mostly $30

$40 and onwards

$1 to $5

$10 to $30 mostly $10

$10

$ 4 to $10 mostly $7

$3

A :You can provide us anything a graphical bitmap file or even a camera taken picture it's recommended that it has to be straight and even 8f it's angled and not perfectly straight it might take more time vectoring it which can add up in cost.

A: You get almost any major filetype that you request usually clients request between these files AI, CDR, EPS, PDF, SVG you also get no background Transparent PNG plus a JPEG Mockup

A: Usually a normal priority order takes in between the same day or the very next day depending on the complexity of the design some designs even takes around 2 to 3 days if highly complex however if something is rush it can be done an hour or two without any extra you just have to let us know but that's free for a few times in a month every second design can't be considered as rush and if it has to be then the roice will vary then.

A: Yes it's possible but sometimes the design shape or dimensions aren't the same because of the side angle artwork.

A: the Standard turnaround is the same day or the very next day first thing in the morning however some detailed designs takes longer we offer custom tailored turnaround too but the Price will Vary accordingly then.

A: usually a normal vector Costs $15.00 USD in most cases however please refer to our pricing Page for detailed analysis Click bellow

Pricing